1

/

of

7

Verira

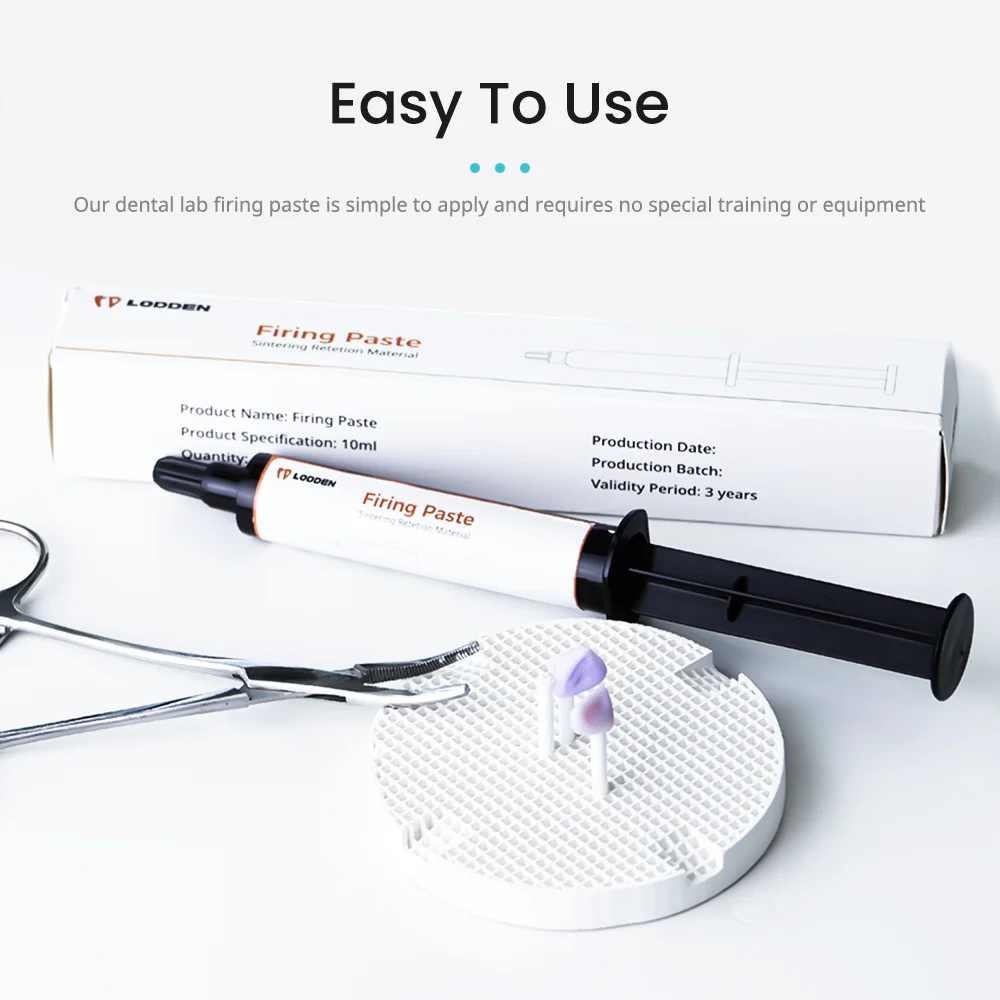

Firing Paste Sintering Dental Lab Paste Sintering Furnace Dental Lab Materials For Veneer Crown And Bridge In Sintering Furnace

Firing Paste Sintering Dental Lab Paste Sintering Furnace Dental Lab Materials For Veneer Crown And Bridge In Sintering Furnace

Regular price

$30.80 USD

Regular price

$30.80 USD

Sale price

$30.80 USD

Unit price

/

per

Couldn't load pickup availability

SPECIFICATIONS

Brand Name: YXSH

Hign-concerned Chemical: None

Origin: Mainland China

Commodity Quality Certification: ce

Model Number: Dental Firing Paste

Material: Dental Firing Paste

Size: 1pcs

Thickness: Dental Firing Paste

Features 1: Dental Restoration

Features 2: Sintering Paste

Features 3: Sintering Furnace

Features 4: Dental Lab Materials

Choice: yes

semi_Choice: yes

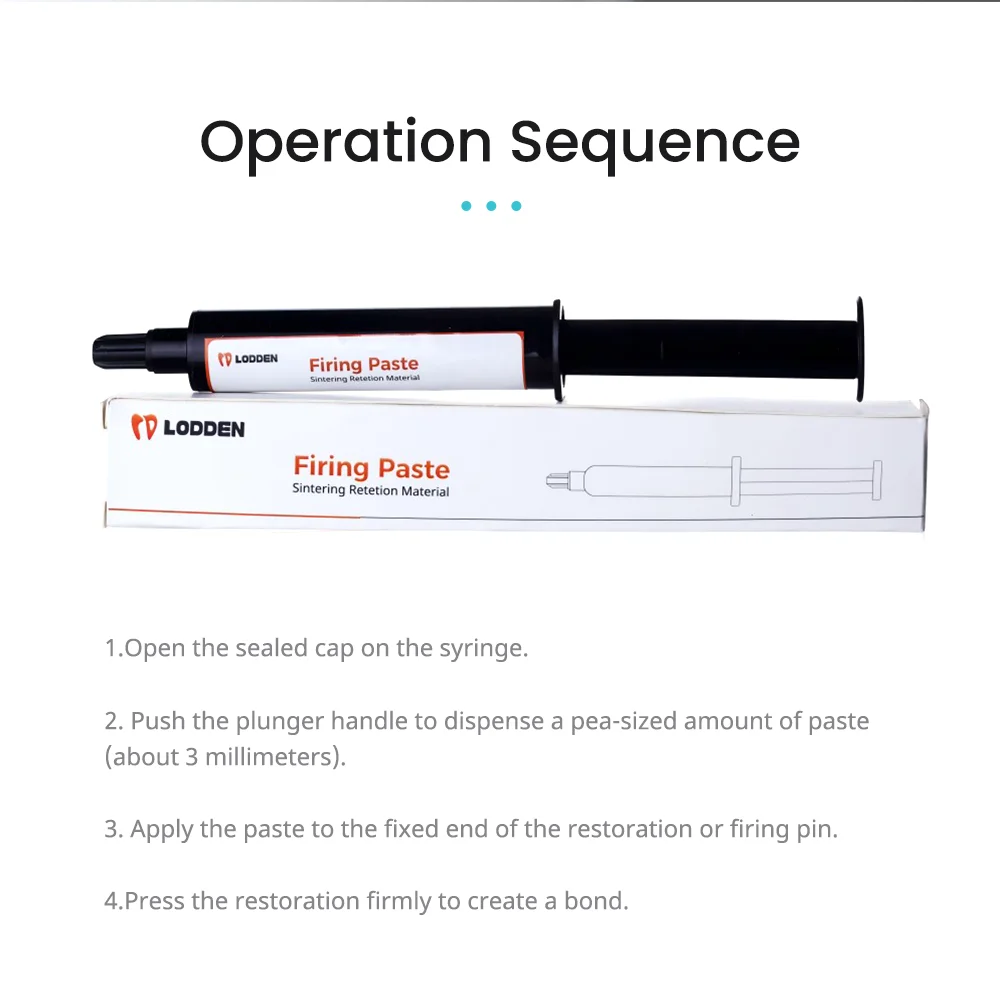

1. Connection and fixing function

In the field of dental restoration, sintered paste is commonly used to connect various dental material components together. For example, when making porcelain crowns, it is necessary to splice the various parts of the ceramic material together, and sintering paste can be used as a bonding medium. It undergoes a series of physical and chemical changes during the high-temperature sintering process, allowing ceramic materials to be tightly bonded together. Just like using glue to stick objects together, sintering paste can ensure that various parts of the dental crown form a complete structure after sintering, improving the overall strength and stability of the restoration.

For some composite restorations containing metal inner crowns and ceramic outer layers, sintering paste can also effectively bond the metal and ceramic. The physical properties such as thermal expansion coefficient of metals and ceramics are different. Sintering paste can act as a buffer and connection between the two, reducing the risk of material separation caused by factors such as thermal expansion and contraction.

2. The function of filling gaps

Dental materials may have small gaps during processing or assembly. Sintering paste can fill these gaps, making the surface of the restoration smoother. For example, when making an all ceramic dental bridge, there may be some small gaps between adjacent dental restoration units, and the sintered paste can fill these gaps after sintering, avoiding the accumulation of food residues and other debris in the gaps, while also reducing the possibility of bacterial growth.

The function of filling gaps also helps to improve the aesthetic appearance of the restoration. Because a smooth and seamless surface makes the restoration look more natural, just like natural teeth, without obvious edges or gaps, thereby enhancing patient satisfaction with the restoration effect.

3. Improve material properties

Sintering paste can interact with surrounding dental materials during the sintering process, thereby improving certain properties of the material. Some sintering pastes contain components that can enhance the hardness of the material. After sintering, these components will diffuse into the surrounding materials, increasing the hardness of the restoration. For example, for some resin based dental restoration materials, after treatment with specific sintering paste, the surface hardness of the material will increase, making it more resistant to wear during daily chewing.

Sintering paste can also improve the chemical stability of materials. It can form a protective film on the surface of the material or undergo chemical reactions with the material, enhancing its resistance to the acidic and alkaline environment in the oral cavity. For example, through the action of sintering paste, the risk of corrosion of ceramic materials when in contact with acidic foods or beverages is reduced, extending the service life of the restoration.

Share